Focos de atención

Artesano, constructor de modelos, fabricante de modelos, carpintero de desarrollo de productos, constructor de muestras, fabricante de muestras, trabajador de muestras, fabricante de modelos a escala, especialista en prototipos de diseño, fabricante de prototipos

When we think of models, we might picture the small model cars or trains that hobbyists like to assemble. But models serve important functions in several industries such as architecture, automotive engineering, and industrial manufacturing!

In manufacturing, for instance, before a product is ready to be mass-produced and sent to stores, it’s got to be tested out. Part of that process is to build prototypes and mock-ups to demonstrate that the product’s design works in real life. The models are then rigorously checked for quality assurance and consumer friendliness before being approved for production.

These detailed product models are carefully crafted by Model Makers to give stakeholders and testers something they can see, touch, and try for themselves. The models are crucial for providing “proof of concept” – and for revealing any underlying problems that may require finetuning or redesign.

Working closely with designers and engineers, Model Makers ensure their finished models accurately represent the intended design and function within the requested parameters. They use hand tools and operate a wide array of machines to create precision parts out of materials like wood, plastics, and metals. They also incorporate other components, such as internal electronic devices, as needed.

Although it’s a relatively small career field, Model Makers are crucial players in the manufacturing industry. Without their hard work and diligence, we wouldn’t have half the products we use and rely on every day!

- Bringing ideas to life through physical models

- Contributing to product development and innovation

- Opportunities to work with advanced manufacturing technologies

- Colaboración con profesionales creativos y técnicos

Horario de trabajo

- Model Makers typically work full-time in workshops, manufacturing facilities, or design studios. Their schedules may have to flex to accommodate deadlines and production cycles.

Tareas típicas

- Examine drawings, blueprints, and technical specifications for proposed models

- Collaborate with engineers and designers to adjust designs, as needed

- Use CAD and CAM software to modify design elements

- Determine dimensions for necessary materials to build models

- Determine the necessary equipment and plan out the sequence of operations

- Program CNC machines to fabricate model parts, or collaborate with CNC machinists or operators

- Ajustar componentes de la máquina como cuchillas, dispositivos de sujeción, etc.

- Determine which blank types to use to create a workpiece. Verify the tolerance of materials to be machined

- Operate machines such as lathes, saws, presses, etc. to create parts or molds

- Mark guidelines and reference points on materials. Use patterns or other references, as needed

- Use hand tools, files, grinders, sanders, hammers, dies, molds, jigs, and other tools, as needed to shape and smooth workpieces to the required dimensions

- Use power tools to insert holes in parts

- Align and join parts using bolts and screws, or via welding or gluing

- Insert mechanical, electrical, and electronic components into models, ensuring proper wiring and soldering

- Examinar los artículos en busca de defectos. Realizar los ajustes necesarios en la maquinaria.

- Utilizar instrumentos de medición para determinar las dimensiones de las piezas fabricadas finales. Verificar que los productos terminados cumplen los requisitos.

- Test prototypes for proper functioning

- Rework parts as necessary to ensure they meet standards

- Present models to stakeholders for feedback and approval

Responsabilidades adicionales

- Keep track of all details such as materials used, final dimensions of parts, production processes, etc. to ensure standardization for future work

- Maintain and repair tools and equipment

- Usar el equipo de protección personal requerido y seguir los protocolos de seguridad establecidos

- Manténgase al día sobre manuales técnicos y nuevas tecnologías

- Mantener la documentación técnica y las hojas de cálculo de datos

- Train and supervise junior model makers and apprentices

- Participate in product development meetings

- Ensure compliance with safety and environmental regulations

Habilidades blandas

- Alerta

- Analítica

- Atención al detalle

- Habilidades de comunicación

- Orientado al cumplimiento

- Creatividad

- Pensamiento crítico

- Disciplina

- Independiente

- Observación

- Organización

- Paciencia

- Planificación

- Resolución de problemas

- Resistencia

- Trabajo en equipo

- Gestión del tiempo

Habilidades técnicas

- Computer-aided manufacturing software like Autodesk Fusion 360, SOLIDWORKS, Solid Edge, Siemens NX CAM, GibbsCAM, Mastercam, etc.

- Computer-aided design programs like Autodesk AutoCAD, CATIA, PTC Creo Parametric, and SolidCAM

- Computer numerical control (CNC) machining

- 3D printing programs

- Knowledge of various materials and their properties

- Hand tool proficiency

- Lectura de planos

- Basic electronics

- Welding and soldering

- Empresas de fabricación

- Empresas de diseño

- Estudios de arquitectura

- Film and entertainment studios

- Prototype development firms

- Instituciones educativas

Model Makers are expected to produce highly accurate, detailed models within allotted timeframes. This requires expertise, precision, and often long hours to meet project deadlines.

The work can be physically demanding, requiring fine motor skills and attention to safety protocols. But the satisfaction of turning a concept into a tangible, functioning product can be very rewarding!

3D printing and CAD software have revolutionized model making, enabling more intricate models while reducing production time and costs. There’s also an industry shift towards replacing traditional materials with biodegradable or recyclable alternatives. In addition, companies are turning more to eco-friendly processes that reduce waste and energy consumption.

Another trend is the integration of augmented and virtual reality, allowing designers to project digital models into real-world environments or become immersed in a 3D space for real-time interaction. To some extent, these new technologies are actually reducing the need for physical model-making, but they’re also making it much easier to collaborate on projects remotely.

Model Makers are very hands-on people who might have enjoyed creating things from a young age. They likely spent hours on hobbies such as model building, woodworking, or crafting. Many grew up with a natural curiosity about how things are made!

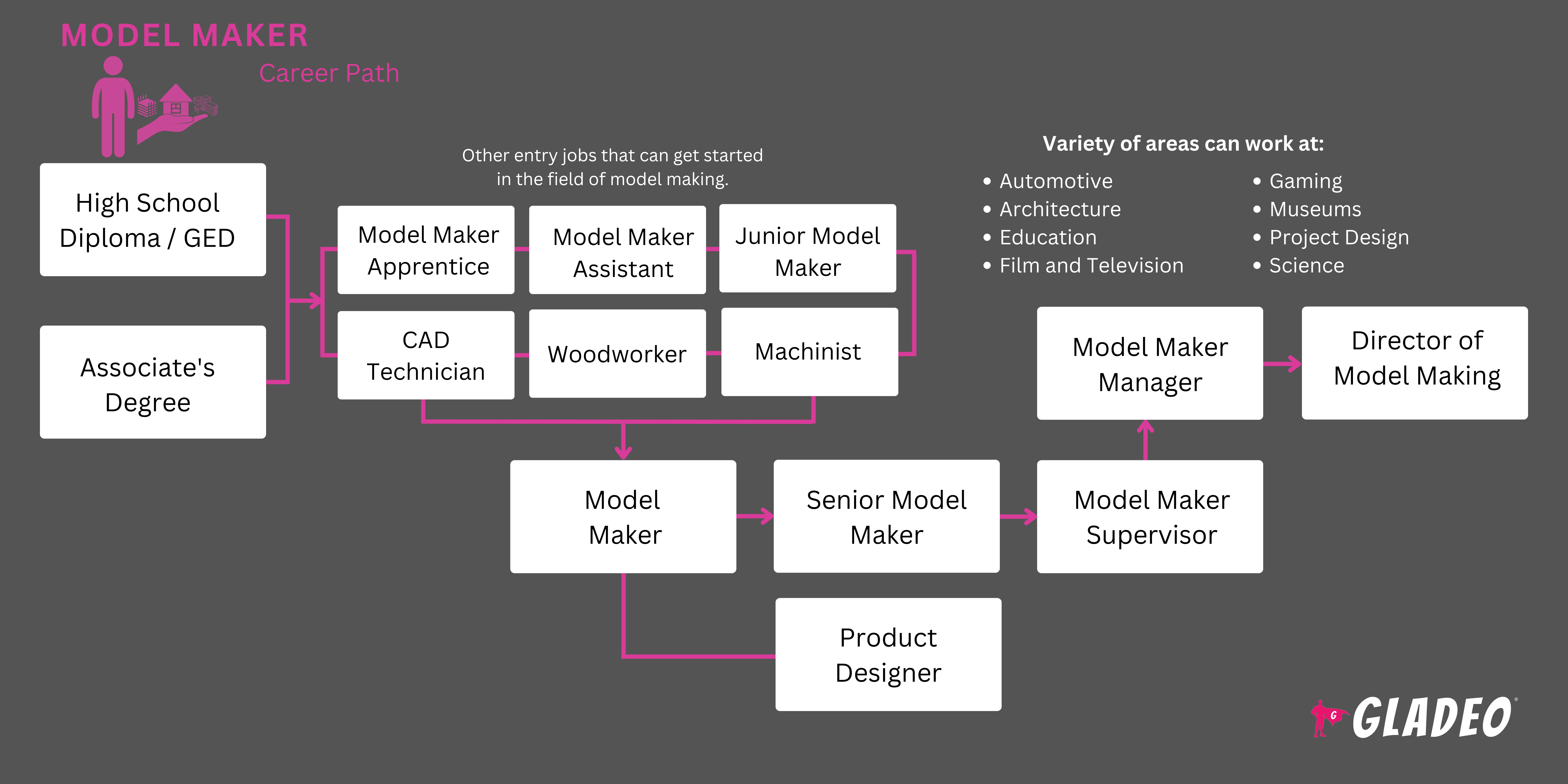

- The educational requirements to become a Model Maker aren’t set in stone

- Some get started with a bit of vocational training or a certificate. Others may pursue an associate degree or even a bachelor’s degree in industrial design, manufacturing technology, or a related field

- Entre los temas habituales de los cursos se incluyen:

- 3D printing

- Lectura de planos

- Programación CAM y código G

- CNC machining

- Diseño asistido por ordenador

- Metrología dimensional

- Procesos de fabricación

- Material science

- Matemáticas (cálculo, trigonometría, álgebra lineal, geometría, estadística)

- Mechanical drafting

- Aplicaciones de fresado y programación

- Prototyping techniques

- Seguridad de la tienda

- Soldadura y unión de metales

- Many Model Makers learn through practical experience via internships, apprenticeships, or related jobs

- Students can learn a lot from online courses such as Autodesk’s 19-hour Intro to CAD, CAM, and Practical CNC Machining offered via Coursera. There’s also a four-month Autodesk CAD/CAM for Manufacturing Specialization which includes a hands-on project!

- Familiarity with augmented reality (AR) and virtual reality (VR) tools can enhance a Model Maker’s capabilities and career prospects

- Model Makers don’t usually need a four-year degree but often take classes related to CAD, CNC machining, industrial design, manufacturing technology, or related fields.

- Look for programs with well-equipped, modernized workshops where you can get practical hands-on experience and learn about the latest technologies.

- Programs should have seasoned faculty members and, ideally, opportunities for internships or cooperative learning with local employers.

- Considere el coste de la matrícula, los descuentos y las oportunidades de becas locales (además de la ayuda federal).

- Think about your schedule and flexibility when deciding whether to enroll in an on-campus, online, or hybrid program. Some courses may be better done in person to get hands-on experience.

- Also consider programs that can train you on using AR and VR tools in relation to model making!

- Sign up for plenty of math (arithmetic, algebra, geometry, and trigonometry), physics, computer science, materials science, design, art, and shop classes in high school

- Considere la posibilidad de aprender dibujo mecánico y lectura de planos

- Enroll in a community college or vocational/technical school program to learn about CAD, CAM, CNC machining, 3D printing, welding, virtual reality, and other related topics

- You can also take online courses from Coursera, Udemy, edX, Pluralsight, LinkedIn Learning, etc.

- Adquirir experiencia en el mundo real a través de trabajos a tiempo parcial relacionados con el mecanizado o el taller.

- Empieza a elaborar tu currículum y añádelo a medida que aprendas y adquieras experiencia laboral.

- Revisar las ofertas de empleo con antelación para ver cuáles son los requisitos medios

- Request to do an informational interview with a working Model Maker

- Haz una lista de tus contactos (incluyendo direcciones de correo electrónico o números de teléfono) que puedan servirte como futuras referencias laborales.

- Study books, online articles, and video tutorials related to model-making

- Join online forums to ask questions and learn from experienced professionals

- Engage with clubs and groups to learn, share, make friends, and grow your network

- Build a portfolio of projects to showcase your skills

- Consulta portales de empleo como Indeed, Simply Hired, Glassdoor y Craigslist.

- Adquiere toda la experiencia práctica que puedas en el taller antes de presentar tu candidatura.

- Consider enlisting in the military in a machinist career field. You’ll get free paid training and can earn job experience that can be used in a civilian career, too

- Seek out apprenticeships sponsored by employers, unions, or trade associations

- Ask a working Model Maker for job-seeking tips

- Considere la posibilidad de obtener un certificado o un título de asociado. Las credenciales académicas pueden ayudarte a destacar frente a la competencia.

- Pide ayuda al centro de empleo de tu escuela para ponerte en contacto con reclutadores y ferias de empleo

- Pregunte a las posibles referencias por adelantado para ver si le recomiendan o escriben cartas de referencia

- Check out online Model Maker resume templates and review potential job interview questions

- Before going into an interview, brush up on the latest news about the field. Be ready to discuss your insights about relevant trends and changes

- Estudia las guías de fabricantes y programas. Conviértete en un experto en los programas y máquinas que utilizas.

- Ask your supervisor how you can improve your CAD, CAM, and CNC machine knowledge and skills to better serve the company

- Knock out specialized certifications related to cutting-edge technologies like AR and VR

- Demonstrate that you can work independently and collaborate effectively on teams

- Train new workers patiently and thoroughly. Make sure to always wear appropriate personal protective equipment to avoid mishaps and hazards

- Escriba artículos prácticos para establecerse como líder del sector.

- Branch out into different types of model-making to expand your horizons

- Considere la posibilidad de trasladarse si es necesario para avanzar en su carrera.

Páginas web

- 3Ds Max

- Instituto Americano de Arquitectos

- Asociación Americana de Constructores de Moho

- Asociación para la Tecnología de la Fabricación

- Asociación de Ingenieros de la Energía

- Association of Professional Model Makers

- AutoCAD

- Autodesk Fusion 360

- Autodesk Inventor

- Blender

- CATIA

- Fabricators and Manufacturers Association

- G2.com

- GrabCAD

- IMAGINEiT

- Sociedad de Diseñadores Industriales de América

- Asociación Internacional de Maquinistas y Trabajadores Aeroespaciales

- Consejo Internacional de Lubricación de Maquinaria

- Sociedad Internacional de Fluidos Eléctricos

- Sindicato Internacional, Trabajadores Unidos de Automóviles, Aeroespaciales y de Implementos Agrícolas de América

- Make:

- Fabricación.gov

- Instituto de Fabricación

- Instituto Nacional de Competencias Metalúrgicas

- Asociación Nacional de Mecanizado y Herramientas

- NX - Unigraphics

- Asociación de Productos Mecanizados de Precisión

- Asociación de Conformación Metálica de Precisión

- Revit

- Shapeways

- SketchUp

- Sociedad de Ingenieros de Fabricación

- Solid Edge

- SOLIDWORKS

- TCT Magazine

- TITANS of CNC Machining

- Trabajadores Siderúrgicos Unidos

- Unity 3D

Libros

- Making Things Move DIY Mechanisms for Inventors, Hobbyists, and Artists, by Dustyn Roberts

- Prototyping: A Practitioner’s Guide, by Todd Zaki Warfel

- Rapid Prototyping: Principles and Applications, by Chua Chee Kai and Leong Kah Fai

Model Makers are key players in the manufacturing industry. But the career field is relatively small, and may not be suitable for everyone, so check out our list of related occupations below for additional career ideas!

- Architectural Drafter

- Técnico CAD

- CNC Programmer

- Montador de equipos eléctricos y electrónicos

- Ensamblador de motores

- Diseñador industrial

- Mecánico de maquinaria industrial

- Machinist

- Ingeniero de fabricación

- Ingeniero Mecánico

- Patternmaker

- Diseñador de productos

- Prototype Technician

- Set and Exhibit Designer

- Structural Metal Fabricator

- Fabricante de herramientas y matrices

Newsfeed

Trabajos destacados

Cursos y herramientas en línea